|

TECHNOLOGY

|

|

|

COMPACT DISC FOREVER!

Why, then, does the part of the audio world that interests us, i.e. those striving for the best sound, stick to the obsolete, physical format of the Compact Disc? Why do I think that it is still one of the best ways to present music? The answer is simple and unambiguous: because it's a long-proven format that was improved numerous times, which guarantees high-class sound, and in special cases – even breathtaking one.

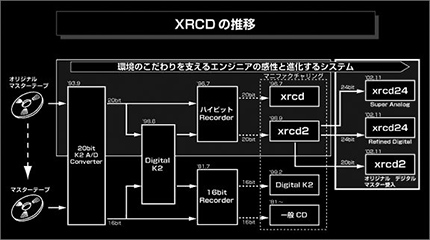

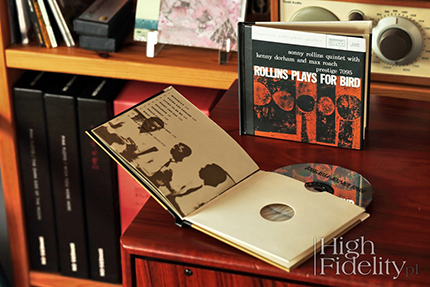

The breaking point in its development was 1995 (according to other sources in 1996). Two parallel methods were presented for the use of this carrier so that it could become something more than it was before. In USA, the HDCDs were presented, and in Japan the XRCDs. In the USA, Keith O. Johnson and Pflash Pflaumer proposed a modification called HDCD - High Definition Compatible Disc, which was a new format, encoding 20-bit words on a classic CD using the clever use of the least-significant bit (LSB). Such a CD was "seen" like a regular 16/44,1 Compact Disc by any CD player, but a player with a HDCD decoder allowed to decode a signal with a resolution close to 20-bits. The solution from Japan, which is not a format, but only a modification of the Compact Disc in accordance with the assumptions described in the so-called Red Book. The Victor Company of Japan, Ltd. (JVC) has proposed discs prepared using techniques known under the comon name XRCD - eXtended Resolution Compact Disc. Also in this case it was about improving the sound resolution available from a CD. | A trial of a trial We wrote about XRCD many times, also in a context of K2 HD recordings (more HERE and HERE). This was, however, a selective research, touching only selected details of this fascinating technique. For a long time, I have felt the need to prepare its synthetic, monographic study. The more I searched for sources, the more I knew about this technique, the more white spots appeared, which without direct conversations with people associated with the creation and development of XRCD could not be fulfilled. And this is almost impossible. There are few written materials on the subject. These are almost exclusively minor notes in the press, promotional texts of the record label and information provided in the booklets attached to discs. Most details can be found in the First Impression Music releases - its owner, late Winston Ma, placed short essays in them. I have not found any continuous publications - neither in English nor Japanese. Which is surprising, because it is one of the deeply Japanese techniques that are characterized by a combination of high technical culture of this country and amazing sensitivity to sound quality.

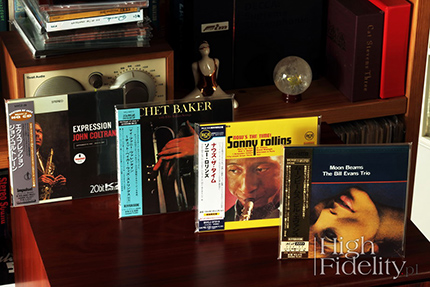

Examples of four generations of K2 (from the left): 20 bit K2 Coding, 20 bit Digital K2, 24 bit K2 Coding and K2 HD The frustration is deepened by the fact that many details are unclear, many are unknown. So I had a choice – I could either abandon this project and continue to explore its periphery, or with full awareness of the fragmentary nature of research results, try to prepare something like a "skeleton" on which later, when I get more information, I would be able to build a more complete knowledge. I chose the second one. However, this is not the end. To keep the article in check I had to give up many details. For example, I have omitted the development of a parallel thread, which is K2. Let's just say that it is something like a "truncated" XRCD. In its case, no A/D conversion is required in the K2 converter, the number of pressed CDs is not limited, or a master tape copy can be used. Interestingly, this technique is now more modern than the XRCD, because with the K2 HD plates another step forward was actually taken.

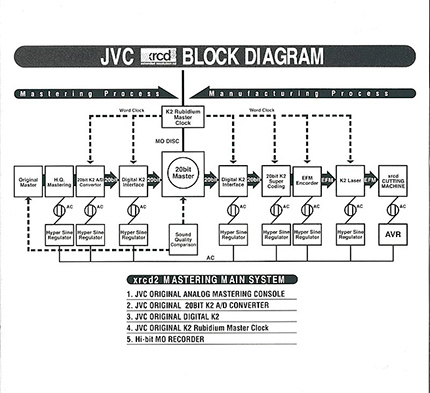

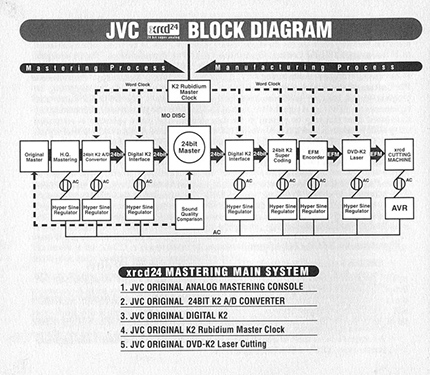

A block diagram comparing the maing of XRCD2, XRCD24 and K2 The article has been divided into two main parts: "Technique" and "Listening" with a "starter" or an introduction to the subject regarding K2 (the technology, not discs). The technical part is divided into three parts: XRCD, XRCD2 and XRCD24. The first one is the longest, because it describes the basic components of the system, which are only modified for the others. Let's get to it!

It's a unique photo of the K2 converter that we have thank to reverb.com, and auction service for professionals It took five years to develop a method of coding such an improved signal - in 1993, a 20-bit K2 A/D converter, model AD-0126, and K2 Super Coding were ready. In K2 Super Coding, 20-bit words were converted to 16-bit ones. Sophisticated dithering techniques were used to keep the high dynamics and resolution. Let's also say that Sony had its own system of this type, called Super Bit Mapping, which in turn used noise-shaping algorithms. In any case - they were the first elements of the chain, completed in subsequent years, which after completion of all the elements became the XRCD system. The next step was, revealed a year later, the K2 Laser Cutting system, which received its own logo, placed on K2 and XRCD releases. This is the second "end" of the whole chain - instead of the typical CD production system, a specially modified laser was used for cutting the glass matrix. It was clocked with an ultra-precise word clock and was powered by devices for regulating the supply voltage. What's more, it burned out longer and more precise pits and and lands - later Yamaha will return to this system in their CD-R recorders with the Audio Master system.

Archive images from press releases from October 1994 covering an opening of the K2 mastering studio Have you seen the Mobile Fidelity discs, eg Santana's Abraxas released in the Ultradisc One-Step technique? These are expensive boxes that include disks cutted with the omission of the father-mother pair. This technique allows making only a limited number of discs, but the sound quality is significantly improved. Together with the K2 Laser Cutting, this technique was introduced for the production of CDs, the making of which resembles in the general framework the process of vinyl pressing. Such CDs were created directly from a metal matrix, that was a copy of a glass matrix. It was possible to prepare 2,000 copies of the title in this way, which meant only mimited ditions could be prepared this way. JVC is faithful to this assumption until today - the titles (actually, we will come back to this again) are not re-issued. TECHNOLOGY

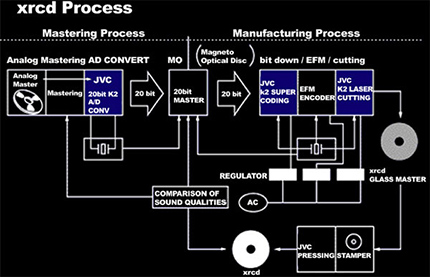

XRCD block diagram It all starts with an analog master tape played on a JVC modified reel-to-reel tape recorder. The signal is then sent to the analogue console designed by JVC, on which mastering is carried out (in the analog domain). After processing, it is converted into a 20-bit digital signal in the K2 A/D converter and recorded on a specially selected medium, which is then delivered to the Yokohama pressing plant. This is another significant change compared to the classical CD production method. The standard back then was the Sony U-Matic 1630 system with digital tape. Material encoded in the form of PMCD or DDP was sent to the pressing plant, where the glass matrix was prepared. The problem was that this chain was not standardized, everything was based on the assumption that the tape recorders on the mastering studio and pressing plant were the same. People from JVC decided to eliminate this link and as an intermediate carrier they chose a magneto-optical disc (MO), also from Sony.

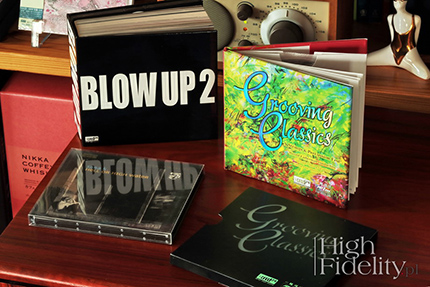

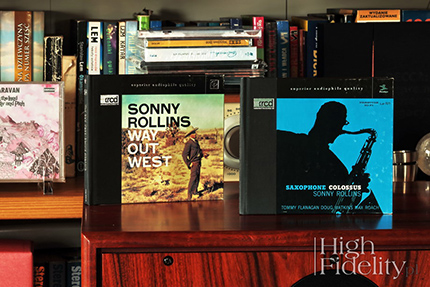

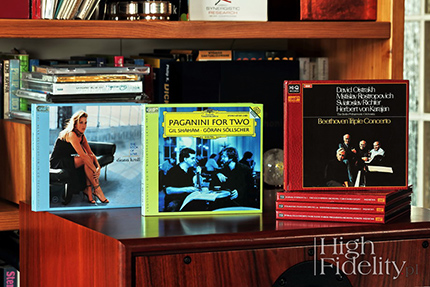

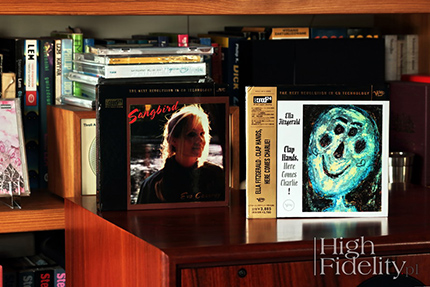

The XRCD discs from the Japanese format "branch". Please pay attention to the way it is made - it's a digipack type, with cardboard covers and a booklet, that reminds a smaller version of 78 rpm LP albums, in other words, the work of Alex Steinweiss from 1939. They are also slightly smaller than releases from the American "branch", as they measure 142 x 125 mm. There are versions with OBI and without it, there are also - even more limited - editions of the mini LP with gold OBI. The exception are titles issued by TBM, with a height of 134 mm. This is the ancestor of the Mini Disc - the disc was the same size as a CD and was locked in a cassette. To write some content, a high-power laser melted the surface, and the magnetic head recorded the signal in a deeper layer. This system was fantastic because it guaranteed an extraordinary recording durability, far exceeding the tape (and then also CD-R discs). What's more, it allowed to write a 20-bit signal (44.1 kHz). The device that was selected for this task was the Sony PCM-9000 recorder. The SDIF-2 interface was selected for digital signal transfer. The value of this solution and its quality is evidenced by the fact that it was not until 2016 that JVC decided to use DVD-R and BD-R discs and still only for selected titles, even though the format itself has been "dead" for years and PCM-9000 has not been produced anymore. Not only the MO disk was sent to the JVC press, but - literally – also the recorder on which it was burned. There, in the K2 Super Coding converter, the 20-bit signal was converted to a 16-bit one, and then it was re-clocked with 128x oversampling, which gave dynamics of 108 dB and THD of -96 dB. The signal prepared in such a way was then coded in EMF (the format used in the pressing facility), and the laser with the K2 Laser Cutting system burned out the glass matrix. The system re-clocked the signal, eliminating the jitter residue. Each of these elements was controlled by an external, precise Pro Box 12 word clock and was powered by regulated voltage. A single glass "stamp" was prepared, from which then a single metal matrix was made, that allowed 2000 discs to be made of it.

Master Disc Recorder Sony PCM-9000. An image from JVC mastering studio. Below you can see a custom-made mastering console Although it is a digital record, a common consensus says that when the matrix wears off, the accuracy of the stamping deteriorates and, consequently, the sound deteriorates. This principle was also used by other record labels, such as First Impression Music, which offered two versions of UltraHD CD – a "regular" one and limited edition (first 2000 copies). After burning the test disc, it returned to the mastering studio, where it was compared to both the analog master and the 20-bit version on the MO disk. It was not until the material was approved that the pressing started. Each of these elements was selected after long listening sessions, not by accident. How much time, energy and money was involved in this project can be demonstrated by the following story. When the idea for XRCD arose, JVC's mastering engineer and producer, Akira Taguchi, went to his friend, who ran a record shop in Yokohama (JVC studios are also located in the same city). He convinced him that it was worth trying a different approach to pressing discs and together they prepared about twenty different discs with the same musical material, differing in the way of making them and the materials of the base layer of the disc. And let me remind you that until then only two types of material have been used: aluminum and gold. As Mr Alan Yoshida, another JVC master mastering engineer, but working at A & M Mastering Studios (Hollywood, California) said in an interview for Billboard magazine in 2001, together with other engineers from that studio, Dave Collins and Andrew Garver, and Mr. Akira Taguchi, they tested all available combinations. Thanks to the precise description of all the changes, they were able to accurately indicate changes that - according to them – contributed to a better sound: It was a dream come true - knowing that I could do it. We could change, for example, one cable by moving it somewhere else in a system, and they [pressing plant workers - ed.] documented it all like crazy people. We've tried all the combinations we've had in the digital domain in this way. It was amazing.

They also tried then different material to cover the discs - aluminum and gold and even - absolutely exotic for this purpose - copper. In the consistent opinion of all involved parties, aluminum yielded the best results. That is why it is still the only material on which XRCD discs are pressed.

The XRCDs of the American „branch” of the format. These are mini LP-like discs with cardboard covers and a booklet, but without a characteristic "tape" on the side, as in 78 rpm albums. They are larger than discs from Japanese "branches" and measure 144 x 134 mm. It is no coincidence that I hailed Mr. Yoshida and it was no coincidence that A & M Mastering Studios appeared here. The place of "birth" of the XRCD system is Japan and it "nursery" was Flair Studios Victor Company of Japan, Ltd. This system had its premiere in Japan, however, the limitations were quickly realized. And the basic assumption was that the source of the signal MUST be an analog master tape. At that time, shipping them to Japan was very rare and expensive (insurance), thus the A/D conversion had to be carried out where the tape was stored - in the case of jazz music most often in the US, and when it came to classical music, in the United Kingdom or the United States. In USA, the A&M Mastering Studios was selected for this purpose. It was founded in the place of another legendary place, United Recording Studios, where they recorded Ella Fitzgerald, Count Basie and Joni Mitchell, that operated since April 1967 (more onamrecords.com, accessed: Apr. 20th 2018). The A&M Mastering Studios was closed in 1999, when its owner, PolyGram, merged with Universal Music Group. In its place in 2001, the Ocean Way was founded, where the titles from the XRCD series were still remastered. This is where the "master" tapes went - they were played on a special, modified tape transport, and then the signal was transferred to a MO disk. In both studios - Japanese and American - the Studer A-820 tape recorder was used, but with different electronics. Mr. Yoshida mentioned in interviews several times that in his studio only the mechanism remained from the original tape recorder, and the electronics were made by people from A&M Mastering Studios. Let us add that many titles, such as Three Blind Mice, Proprius and others, were mastered in Japan. In this way, two separate series of XRCD discs were created. The first one, Japanese, mainly used material mastered at A&M Mastering Studios, as well as tapes available in Japan. The chief sound engineer at A&M was Alan Yoshida, but the work was carried out under the supervision of Mr. Akira Taguchi, director of Flair Studios, who then dealt with digital signal processing (the K2 system and pressing) in Japan. Perhaps this is why on XRCD discs from the Japanese “branch" we can find a large "Digital Mastering" inscription, absent from the American “branch”, even though mastering in both cases was done in analogue domain. The American “branch” was mastered by Mr. Yoshida himself, and his department was called JVC America Co. In both cases, the discs were pressed in Yokohama, and the covers were made - for each line, respectively - in Japan and the USA. |

logo + block scheme of XRCD² In this way, we discussed the technological sequence that is the basis of the XRCD system. As you can see, it connects two sides of the process, that results in a CD: "Mastering Process", which is the mastering part and "Manufacturing Process", i.e. the process of replication, the connector of which is a magneto-optical disc (MO). I also pointed to the creation of two mastering centers - in Japan and the USA - whose common “element” was Mr. Akira Taguchi, director of Flair Studios, belonging to the Victor Company of Japan, Ltd.

The XRCD2 discs were prepared by both "branches" of JVC, and yet in the Japanese one there are both "formats" available: a digipack and a bigger, even higher – the Three Blind Mice was one of the most devoted clients of the JVC studios. Both, however, resemble 78 rpm LP albums. In turn, American versions are smaller with their 127 mm. As you can see, one of the most important goals of these activities was to minimize jitter, ie time distortions occurring in the digital signal. Work on new solutions led to the creation of the Digital K2 converter in 1998. This device had only one purpose: to minimize jitter. It was included in the XRCD-making chain, both on the mastering and replication side. To mark this, a separate Digital K2 logo was created, and the discs prepared in this way starting from the same year were marked with the XRCD2 logo. Same as before, mastering was performed both in Japan and in the USA. Let us add that the Digital K2 has become the basic tool used to make K2 discs. Another novelty was the introduction to the mastering and replication system of a Rubidium Clock, that was 10,000 times more accurate than the ones used previously. It was used for all devices involved in this process.

The end of the 1990s was dominated by the video DVD format and attempts to sell music on hi-res discs - DVD-Audio and DSD. The recording studios were already equipped with 24-bit recording and mastering systems, which forced the JVC's reaction. In 2002, a new version of the XRCD system called XRCD24 debuted - the person chosen for the international premiere was Mr. Winston Ma, who specially for this occasion created a sub-label Lasting Impression Music that released the Growing Up In Hollywood Tour by Lincoln Mayorga and Amenda McBloom (LIM XR 001). The material acquired from master tapes, recorded in parallel with the recording used for the LP direct-disc release, was used to evaluate the new system in the Flair JVC Mastering Center studios. Their director at that time was Mr. Tohru Kotetsu, who leads the studio to this day. The transition to the 24-bit platform was started by replacing the replication system. Instead of the previously used CD laser, a specially modified K2 DVD laser was used, which even more precisely prepared the glass "master". The system was called "Extended Pit Cut". Later a similar technique will be used by Sony creating Blu-spec and BSCD2 discs, for which the glass matrix is burned with a modified laser originally intended for Blu-ray discs.

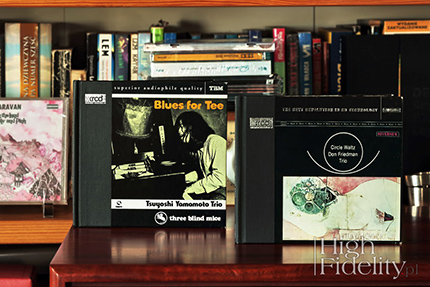

Block diagram of the XRCD24 In XRCD24 making process, there were also new analogue-to-digital K2 converters, as well as the K2 Digital signal regeneration system. It also turned out that the MO recorder used from the very beginning was able to save 24-bit words as well. The discs featured inscriptions already known from XRCD2, ie "The Next Revolution In CD Technology", and some used the same as for XRCD and XRCD2 - "Superior Audiophile Quality". The XRCD24 system was conceived as something bigger than the previous versions, which can be seen in the repertoire - a lot of different record label release their disc with this logo. While the previous releases had a uniform graphic design, the new ones often differ from each other often beyond recognition. More important, however, is the change in the approach to the source material. You probably remember that one of the assumptions was to acquire analog "masters", right? This path has been preserved now, but the digital recordings were no longer excluded, and both types of remasters were distinguished by a logotype - under the XRCD24 logo with a material remastered from the analog tape we can find the inscription "24-bit Super Analog" and when digital material is used, the " 24-bit Refined Digital ".

Mr Winston Ma (FIM / LIM) was a big fan of the XRCD24 and he was entrusted with the debut of this system outside Japan - in the photo, a Sheffield Labs release, the second title released in this format. The next titles from FIM are Decca's remasters (in the middle). Two years later, remasters of EMI master-tapes received almost identical graphic design (on the right) You can hardly find any information in English about how they differ, and only the booklets one can find in Mr. Kazuo Kiuchi, now the main shareholder of the XRCD24 system, releases one give some details: The XRCD process starts from mastering. The original digital master is converted to analog using specially designed K2 D/A converters ("24 bit Digital-To-Analog Converter"). The signal is then mastered using a modified console and converted to digital using the new K2 A/D converters („24 bit Analog-To-Digital Converter”). As you can see, almost the entire chain known since the XRCD introduction is present here. The only change is the transition to 24-bit words and, for the "24-bit Refined Digital" version, conversion of digital signal into analogue and mastering it done in the analog domain. In this way, an analog "master" signal is obtained, which is mastered in the analog domain and converted back to the digital form. Although this means adding two conversions, the effects are great. Let me add that the digital-to-analog converter used in JVC studies is almost certainly Reimyo DAP-999EX TOKU (High Fidelity Edition). It is also a comon knowledge that they use Harmonix X-DC Studio Master Million Maestro power cables in the studio.

Mr. Kazuo Kiuchi, the owner of Combak Corporation, is one of the main shareholders of the XRCD24 format. He produced the Diana Krall and Deutsche Grammophon releases, all “24-bit Refined Digital” (on the left). But he is also a master of fully analog versions, like those released by the English company Hi•Q Records (on the right), and in Japan by his label Master Music (see photo opening article). What's next? In the middle of the first decade of the 21st century, the JVC began to flirt with new pressing techniques. Next to the recalled XRCD2 logo, the new, SHM-CD logo also appeared. Super High Material CD is a technique developed jointly by Universal Music Japan and JVC. Instead of the previously used polycarbonate, i.e. a plastic from which the disk is made, the material used for the production of LCD displays has been used, that has much better optical and mechanical properties. Still, however, aluminum is used as a reflective layer.

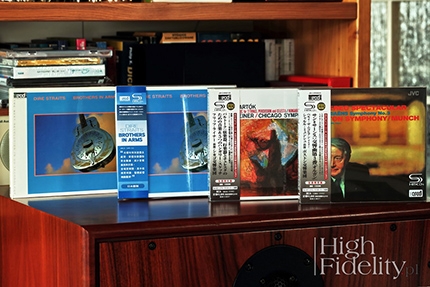

After the development of SHM-CDs by Universal Music Japan and JVC, the re-issues of titles released on XRCD and XRCD2 began to appear - unfortunately, it is not known whether new matrices were cut for them. Most often the combination of XRCD, SHM-CD, and HR Cutting logos can be found on releases with classical music. Dire Straits Brothers in Arms was originally released as XRCD2 and then as SHM-XRCD2 (on the left) The first titles were released in 2007 and it was both classical music and the Brothers in Arms by Dire Straits and Hell Freezes Over by The Eagles. This is of course interesting, but even more interesting is the fact that in this way titles already published in XRCD and XRCD2 systems have been re-issued. Perhaps, the new glass matrices were prepared from 20-bit digital material stored on MO disks. But there is something else. You can fins in stores discs with XRCD, SHM-CD and HR Cutting logos. HR Cutting is the technique used for the first time for the production of Platinum SHM-CDs, that is based on the high definition signal (24-bit, 176.4 kHz) being transferred to the pressing plant on a DVD-R or BD-R disc, and it is converted “n-the-fly” to CD's 16/44.1 format when burned on the matrix. Having said that, let me remind you that one of the original assumptions of the XRCD was the "regeneration" of the digital signal after its conversion to 16-bit. Therefore, it is not known how it actually works with these discs.

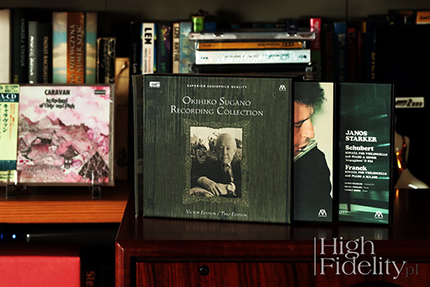

With the Okihiko Sugano Recording Collection album we were informed that apart from MO also DWA station can be used for mastering The next alterations concern XRCD24 discs. In the special box booklet titled Okihiko Sugano Recording Collection one can find a diagram showing the modified XRCD making chain. Neither the description nor the diagram itself are precise in the English version, but one thing is immediately obvious: instead of the Sony PCM-9000 recorder in its central point, a specialized computer known as DAW - Digital Audio Workstation is marked. The description talks about the Pyramix and Nuendo systems. It seems that the signal is upsampled in the Nuendo processor. Also these discs were prepared using the HR Cutting technique. Thus, the glass matrices of XRCD24 can now be prepared using either the PCM-9000 recorder or with DVD-R or BD-R discs; the latter are necessary if we use the HR Cutting technique. It requires that the signal before converting it during master burning should have the 24/176.4 parameters, and the PCM-9000 provides a 24-bit signal, but only with a sampling frequency of 44.1 kHz. SOUND The core of the XRCD system, despite many amendments, improvements and changes, has remained unchanged since 1996. A novelty was the transition to 24-bit words, the introduction - next to the magneto-optical recorder - of the DAW station, flirtation with SHM-CD and the use of HR Cutting technique. In the case of XRCD24 discs, attention should also be paid to the admission of a digital master, as well as the opening to a wide spectrum of music. Such diversity usually means that it is difficult to establish one, common "pattern". The easiest way to do this is with the XRCD and XRCD2 disks, because they were prepared by the same engineers and according to clear rules. Their sound is unbelievably saturated. The sound is focused around the middle of the band, and the dynamics are outstanding. Compared to the best SACD editions, not all titles turn out short (quality wise), often – at least for me – the XRCD and XRCD2 discs sound better than hi-res discs! Based on listening sessions, it can be stated that the Japanese already in the 1980s knew something that we discovered years later, namely that the resolution is not the same thing as “highly detailed”, but rather an abundance of sounds that build something more than just a "surface".

The XRCD24 discs from the Japanese "branch" were released both, in the format known from previous systems, as well as in the format previously reserved for discs issued in the USA. The discs are available both with OBI and without it. Therefore, most XRCD discs sound at first dark and deep. This is especially striking when we compare the titles of popular music, say Diana Krall and Dire Straits. Also, the sound stage is built differently - it is deep and dense, but does not create a "holographic" effect, because it seems to be focused around the listening axis. Our reception changes, however, with our personal as well as of our system's development. It turns out then that what we took for a dark sound is a natural velvetness, and the lack of "wow!" effect is actually a neutrality. The XRCD24 discs offer a more differentiated sound, because the material for them comes from various sources, both analog and digital. However, even among them richness, calmness and density are dominating features. They do not always offer such a perfect resolution and outstanding dynamics as the XRCD and XRCD2s, but the effects are still better than with standard releases. You can also point to a few series whose sound is simply outstanding. One of them is the series prepared by First Impression Music, that is Mr. Winston Ma. As I said, FIM was the first label to present XRCD24 outside of Japan. A dozen or so Decca's titles have been released with its logo, often spectacular ones, such as Verdi's Choruses (LIM XR24 018) and Albéniz Suite Epsañola (LIM XR24 068). In addition to remarkable sound, they are distinguished by a special design - the front creates a "window" under which you can see the original cover. "Direct From Original Master Tape" is printed on top. Two man behind this project are Mr. Winston Ma and Chi Ho Yeung from the Canadian company Chi Ho Design. Two years later, a remarkably similar project was used for the re-edition of EMI recordings, bearing the inscription "Original Master From Abbey Road Studios".

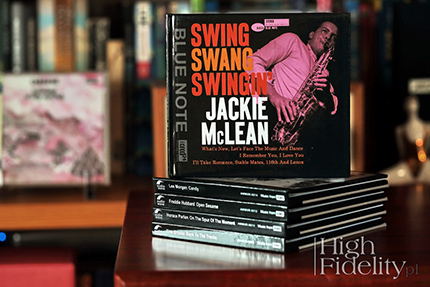

The most important attempt in recent times to transfer Blue Note recordings - XRCD24 releases from Audio Wave Music. The second group consists exclusively of recordings of classical music. Hi-Q Records releases both LPs and XRCD24s. Remastering is carried out in the analog domain, and the whole project is supervised by Mr. Kazuo Kiuchi, the owner of Combak Corporation (Reimyio, Hijiri, Harmonix). The visual design resembles the releases of XRCD and XRCD2 from the American "branch" of the record label, but the size of the "Japanese" series. Mr. Kiuchi is also responsible for the stylistically diverse Master Music series, and earlier he had released the Deutsche Grammophon titles on XRCD24, and two Diana Krall albums. There is also a completely unique series with Blue Note recordings, published by the Audio Wave Music. We wrote about it in the report of the 70th meeting of the Krakow Sonic Society. Since then, I have appreciated it and understood what this sound is all about. And it is very similar to the XRCD discs prepared by Alan Yoshida. And no wonder, the owner of the brand is the Ocean Way Mastering studio, the producers are Joe Harley, Robert Bantz and Kevin Berg, i.e. people from A&M Mastering Studios, and the mastering was done by... Alan Yoshida. SUMMARY I have been preparing this article for almost two years, gathering information, buying discs, listening to them and comparing them with other versions. Based on these experiences, I can responsibly say that all XRCD versions offer above average sound quality and individual titles sound phenomenal. The most differences within the series can be found in the case of XRCD24, because the recordings come from so many sources that it was not possible to maintain a consistent "style". Also, the introduction of the sub-category of recordings based on digital tapes has modified this picture. These are still excellent transfers, often better than the Platinum SHM-CD and SACD versions. However, not always, which shows that new developments and techniques are also valuable and noteworthy. A strict control over the entire signal processing chain, from the "master" tape to the replication ensured by JVC studios, is, however, something like a "quality stamp". Buying Platinum SHM-CD and SACD discs we can't be sure what kind of sound to expect. Probably a good one, but we can't be absolutely sure. In turn, XRCD discs, in any form, ensure a very high sound quality level and which gives us certainty that with them we get the top version of the title. It is amazing, that more than thirty years ago, when developing the K2 system, the Japanese knew something that we have been discovering only recently. Chapeau bas! |

t is 2018, and we live in a time of nonphysical ways of transporting musical content. The basic channel of sales, presentation and promotion of music is currently the Internet and streaming services, with a small addition of stores selling music files. And these are a fulfillment of the most secret dreams of engineers who always wanted to encode as much information as possible. It became possible thanks to hi-res files, or PCM files from 24/88.2 up, as well as DSD files.

t is 2018, and we live in a time of nonphysical ways of transporting musical content. The basic channel of sales, presentation and promotion of music is currently the Internet and streaming services, with a small addition of stores selling music files. And these are a fulfillment of the most secret dreams of engineers who always wanted to encode as much information as possible. It became possible thanks to hi-res files, or PCM files from 24/88.2 up, as well as DSD files.